Specifications

| Connection Inlet Flange | DN 80 ASA/ANSI 3" |

| Connection vacuum outlet flange | DN 50 ASA/ANSI 2" |

| Cooling Method | Water Cooling direct |

| Pressure Ultimate | 1.00 |

| Power Supply Voltage | IEC flange without motor |

| Power Total Rated | 11000.00 |

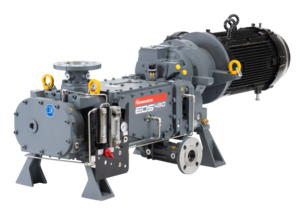

EDS480 HazLoc - Chemical Dry Screw Pump, IEC flange without motor 50 Hz, ATEX

Variant

Explore the range of variants given below to compare the product

| Short Description | Part Number | Power Supply Voltage | Power Supply Frequency | Certification Motor | Power Total Rated @60Hz | Power Total Rated @50Hz | Power at Atmosphere Continous | Flow Cooling Water Min | Temperature Cooling Water Max | Flow Purge Gas Ballast |

|---|---|---|---|---|---|---|---|---|---|---|

| A41842945 | 3Ph 230/400V 50Hz | 50 Hz | CE | - | 11000.00 | 11000.00 | 1.333 × 10⁻⁴ | 303.15 | - | |

| A41842985 | IEC flange without motor | 50 Hz | - | - | 11000.00 | 11000.00 | 6.667 × 10⁻⁵ | 308.15 | 235.61 | |

| A41842986 | Bareshaft without motor | 60 Hz | - | 11000.00 | - | - | 1.333 × 10⁻⁴ | 303.15 | - |

Dry Screw Pumps

Vacuum dry screw pumps are positive displacement pumps that are designed to operate in rough application conditions. These products do not use any lubricant in the pumping mechanism to seal therefore the are defined as dry compressing machines. They offer high pumping speed and can handle a wide range of gases and vapors. These pumps are ideal for applications in the industrial, chemical, pharmaceutical, and semiconductor industries, among others, where oil-free and contamination-free vacuum is required. They have a compact design and require minimal maintenance, making them a reliable and cost-effective solution for many vacuum applications.

EDS Dry Screw

The EDS dry screw pumps feature an innovative design which creates a new benchmark in the screw pump market with second-to-none contaminant handling capability in the harshest industrial conditions. Available in Air and Water-cooled variants, an intricate piece of engineering, built to the exacting standards and quality demanded by our customers, this dry screw pump provides you with a trouble-free and cost-effective solution to meet your needs.

Features and Benefits

- Direct cooling, Bare-shaft options for flexibility, enabling global ExP certification in any region, Standard Cat2 ATEX offerings, Purge gas flow monitoring as standard for optimum uptime and tailored process configuration (inherited)

General Product Information

| Connection Inlet Flange |

DN 80

ASA/ANSI 3" |

| Weight | 520.00 |

| Connection vacuum outlet flange |

DN 50

ASA/ANSI 2" |

| Leak Rate | 1.000 × 10⁻⁴ |

| Power Supply Phase | 3-Ph |

| Power Supply Voltage | IEC flange without motor |

| Dimension Length | 1.69 |

| IP Rating | IP54 |

| Power Supply Frequency | 50 Hz |

| Dimension Height | 0.589 |

| Dimension Width | 0.570 |

| Noise / Sound Level | 72.00 db(A) |

| Cooling Method | Water Cooling direct |

| Connection Inlet / Outlet Flange | DN 80 / DN 50 |

| Dimension Comments | The dimensions length, width and height try to describe the outer shape of this particular product in its typical orientation when standing on the ground. We always recommend checking the detailed dimensions given in 2D drawings in the instruction manual or the 3D shapes given in 3D models. |

| Hazard Certification | ATEX |

Environmental Conditions

| Temperature Ambient Operation Max | 313.15 |

| Temperature Ambient Operation Min | 278.15 |

| Temperature Ambient Storage Min | 243.15 |

| Temperature Ambient Storage Max | 323.15 |

Performance Data

| Power Total Rated | 11000.00 |

| Power Total Rated @50Hz | 11000.00 |

| Capacity Water Vapour |

8.333 × 10⁻⁴

8.333 × 10⁻⁴ |

| Pressure Ultimate | 1.00 |

| Nominal rotational speed | 125.00 |

| Power at Atmosphere Continous | 11000.00 |

| Power at Ultimate | 4500.00 |

| Pumping Speed Air Nitrogen (@50Hz or max @default setting) | 0.128 |

Lubricants

| Default Oil Type | ULTRAGRADE™ Endurance Extend 110 |

Operation Conditions - Limitations

| Pressure Absolute Inlet Continous Max | 1.013 × 10⁵ |

| Flow Cooling Water Min | 6.667 × 10⁻⁵ |

| Temperature Cooling Water Max | 308.15 |

| Pressure Absolute Outlet Continous Max | 1.100 × 10⁵ |

| The specific conditions to operate the machine reliably and safely like cooling water flows, purge flows and so on, and in detail described in the instruction manual please read the correct sections of the manual. | |

| Flow Purge Gas Ballast | 235.61 |

Material of Construction

| Material of Construction | Cast SG Iron, PTFE and fluroelastomer, Cast grey iron, steel, aluminium, brass, rubber |

| Material Rotor | Cast Iron GGG40 |

Classification

| Classification Product Pressure Range | Medium Vacuum: 1 mbar - 1·10⁻³ mbar |

| Classification High / Medium / Rough Vacuum pump | Medium Vacuum Pump |

| Classification Dry or Wet Pump | Dry |

| Classification Vacuum Pump Technology | Dry Screw Pump |

- A41803880 - Instructions.pdf - English - Instructions

- 301273819 - Instructions.pdf - English - Instructions

- 3602 113 9 01_Edwards_EDS Industrial_Brochure_12P_EN_2020_web.pdf - English - Sales Material

- 3602116101-EDS-480-Chemical-Datasheet-EN-Web.pdf - English - Sales Material

- 3602118201-EDS-Chemical-EN-Web.pdf - English - Sales Material

- A41803883 - Instructions.pdf - French - Instructions

- 3602118203-EDS-Chemical-FR-Web.pdf - French - Sales Material

- A41803882 - Instructions.pdf - German - Instructions

- 3602118204-EDS-Chemical-DE-Web.pdf - German - Sales Material

- 3602118295-EDS-Chemical-JA-Web.pdf - Japanese - Sales Material

- 3602118297-EDS-Chemical-KO-Web.pdf - Korean - Sales Material

- A41803857 - Instructions.pdf - Russian - Instructions

- A41803846 - Instructions.pdf - Simplified Chinese - Instructions

- 3602118217-EDS-Chemical-ZH-CN-Web.pdf - Simplified Chinese - Sales Material

- A41803888 - Instructions.pdf - Spanish (European) - Instructions

- A41803894 - Instructions.pdf - Traditional Chinese - Instructions

- 3602118259-EDS-Chemical-ZH-TW-Web.pdf - Traditional Chinese - Sales Material